At Fenoquímica, sustainability is not a recent goal: we have been working with this vision for over 35 years. Since our beginnings, we have used food and wood waste, as well as recycled materials, as the basis for our production process.

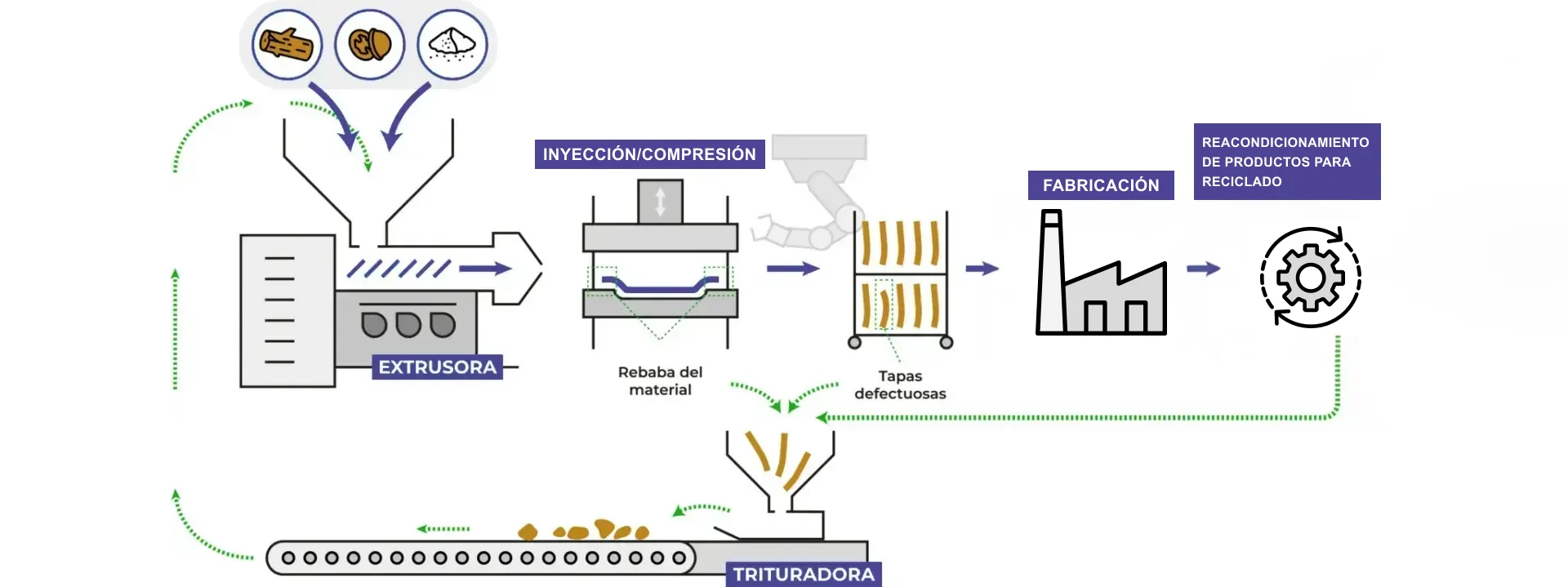

The leftover material from the production of toilet seats at COMSAN is returned to our facilities to be reprocessed and reintegrated into the production cycle. The same happens with lids that do not meet quality standards or have reached the end of their useful life.

In addition to using organic, innovative, and recycled raw materials, we reduce the environmental impact of our production by working with local suppliers and using solar energy at our plant, significantly decreasing our CO₂ emissions.

The result is a 100% recyclable product, with more than 50% of natural origin, offering a sustainable alternative to conventional composite materials that are more polluting.

We use materials of natural origin: wood flour, hazelnut shell flour, and resin.

We crush and reprocess the scrap material and products that do not meet quality standards to manufacture new Versagrit.

1. Utilizamos materiales de origen natural: harinas de madera, de cáscaras de avellana y resina.

2. We crush and reprocess the scrap material and products that do not meet quality standards to manufacture new Versagrit.

3. We only use recycled material for packaging.

The toilet seats manufactured at COMSAN with our material are 100% recyclable, and we work with the goal of incorporating the principles of the circular economy into our production process. We manufacture the material from excess organic components, plant-based and organic sources, and by reusing 100% of the waste generated in the toilet seat production process.

Therefore, we reprocess it and recirculate it for the manufacturing of new toilet seats. In this way, with a 360-degree vision, we recover the wasted material to transform it into consumer goods within a circular economy.

We even repurpose the 1-2% of leftover material from the parts we press, which is then transformed into furniture for both indoor and outdoor use, thanks to a strategic partnership with one of our clients.

We believe in giving materials a second life!

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.