Fenoquímica manufactures thermoset molding powders based on phenolic (phenol-formaldehyde) resin, following the highest quality standards. This ensures full control over the final result and product properties, delivering phenolic materials with excellent technical performance and consistent production quality.

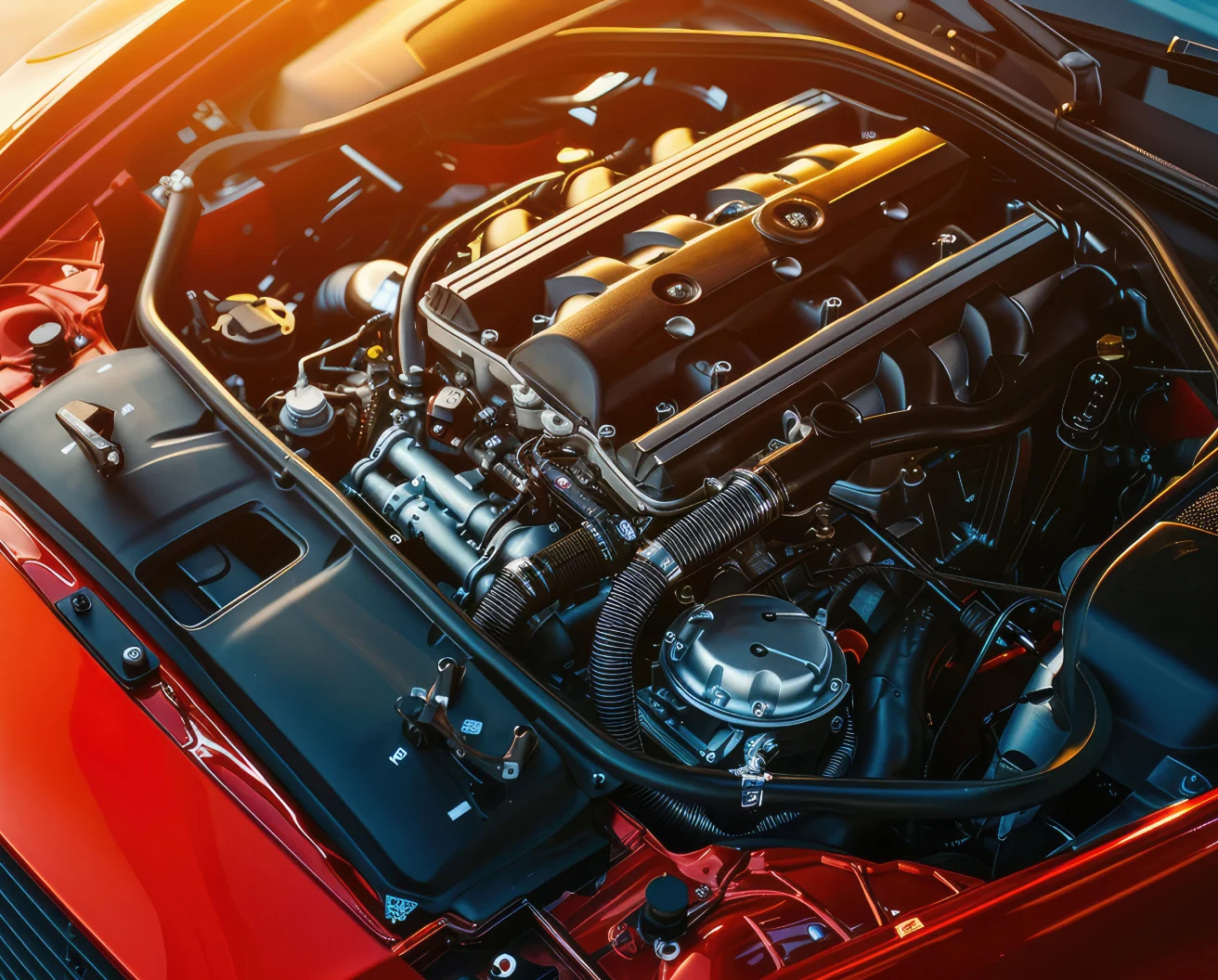

Fenoquímica’s molding powders are designed to provide an optimal balance between technical performance and processing versatility, meeting the demands of demanding industries such as electronics, transportation and home appliances. Their novolac-based composition ensures thermal and electrical insulation, flame resistance, abrasion resistance and excellent resistance to automotive fluids (oil, coolant, etc.).

With a consolidated track record, Fenoquímica is positioned as a benchmark in the development and supply of phenolic resin materials for the transport industry, combining innovation, efficiency and reliability.

They maintain their dimensional stability even under extreme conditions

Excellent stiffness, surface hardness and modulus of elasticity

Good electrical insulation properties

Resistance to solvents, oils, fuels and weathering

Lightweight, contributing to improved vehicle energy efficiency

Ability to replace metal and engineering thermoplastics without compromising performance

Our materials are used in transmission systems, brakes and engine assemblies, increasingly replacing metal components or engineering composites. They are also ideal for electric and hybrid vehicles, in components such as battery systems, motors, transmissions and fuel cells.

High heat-resistant and electrically insulating materials for electrical junction boxes, starter motor brush holders and component encapsulation.

The heat and weather resistance of our phenolic compounds make them ideal for headlamp housings, windshield wiper arms, fuel caps and charging plugs.

Formula

Features

Use

Molding Method

Formula

150

Features

insulating, chemical resistance, dimensionally stable, high fluidity, UL certified

Use

Wear detectors, instrument cases, electrical devices, switches

Molding Method

Injection (high fluidity)

Formula

180

Features

insulating, dimensionally stable, UL listed, IATF approved, low smoke level

Use

Instrument cases, electrical devices, switches

Molding Method

Transfer-compression-injection

Formula

200

Features

insulating, high thermal resistance, high dimensional stability, impact resistance

Use

Automotive, Pulleys, Rollers, Relays, Hard wheels

Molding Method

Transfer-compression-injection

Formula

400

Features

Precise molded parts, High dimensional stability, V0 UL94, Glass fiber reinforced

Use

Automotive, Pulleys, Rollers, Relays, Electrical devices, Wear detector

Molding Method

Injection (high fluidity)

Formula

405

Features

Precise molded parts, high dimensional and thermal stability, glass fiber and rubber reinforced

Use

Automotive, Pulleys, Rollers, Relays, Hard wheels, Electrical devices, Wear detector

Molding Method

Transfer-compression-injection

Formula

410

Features

Precise molded parts, High dimensional stability, V0 UL94, Low smoke, Glass fiber reinforced

Use

Automotive, Pulleys, Rollers, Relays, Electrical devices, Wear detector

Molding Method

Transfer-compression-injection

Formula

415

Features

Precise molded parts, high dimensional and thermal stability, glass fiber reinforced

Use

Automotive, Pulleys, Rollers, Relays, Electrical devices, Hard wheels, Wear detector

Molding Method

Transfer-compression-injection

To provide the best experiences, we use technologies like cookies to store and/or access device information. Consenting to these technologies will allow us to process data such as browsing behavior or unique IDs on this site. Not consenting or withdrawing consent, may adversely affect certain features and functions.